Application Areas

computer boards

cell phone cords

TV boards

copper-clad laminate

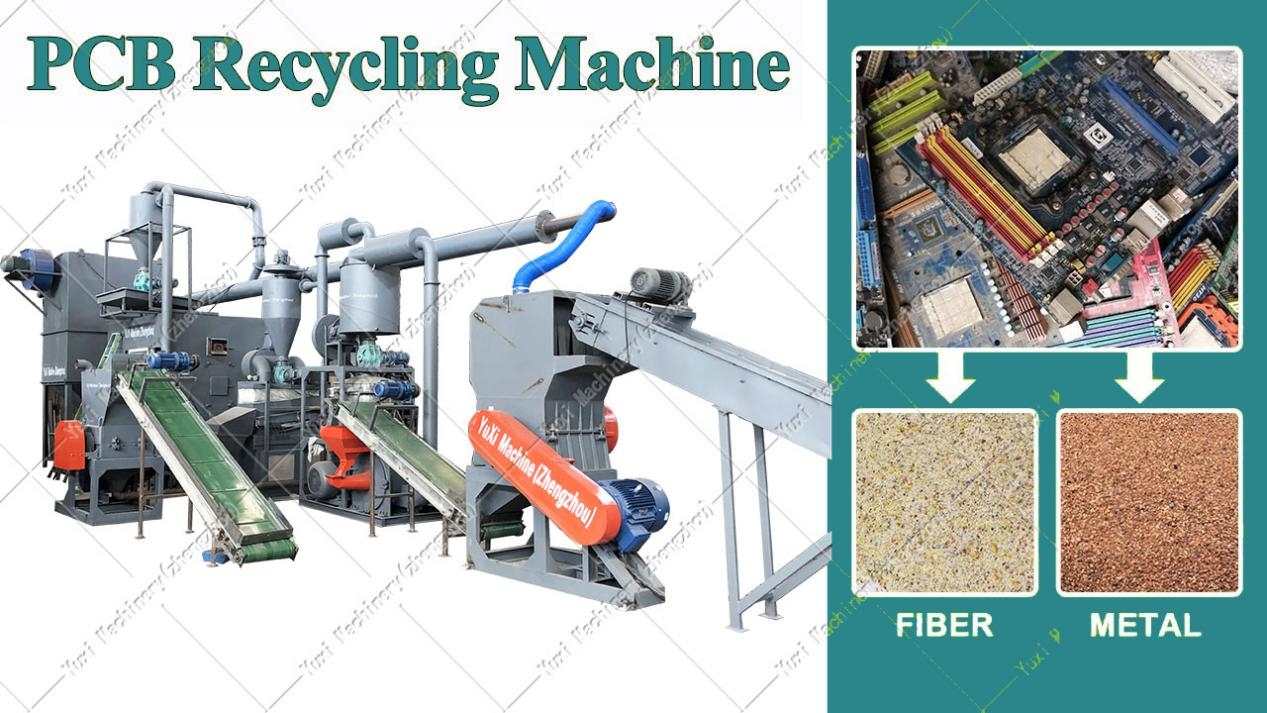

Final Products

Because of the high value of the metals, fiber and resin, there is no doubt that this plant not only help to change waste into treasure, but also bring great economic benefits.Through years of practice and theoretical analysis, we obtain the best separation result, the separating purity can be reached to 99%.

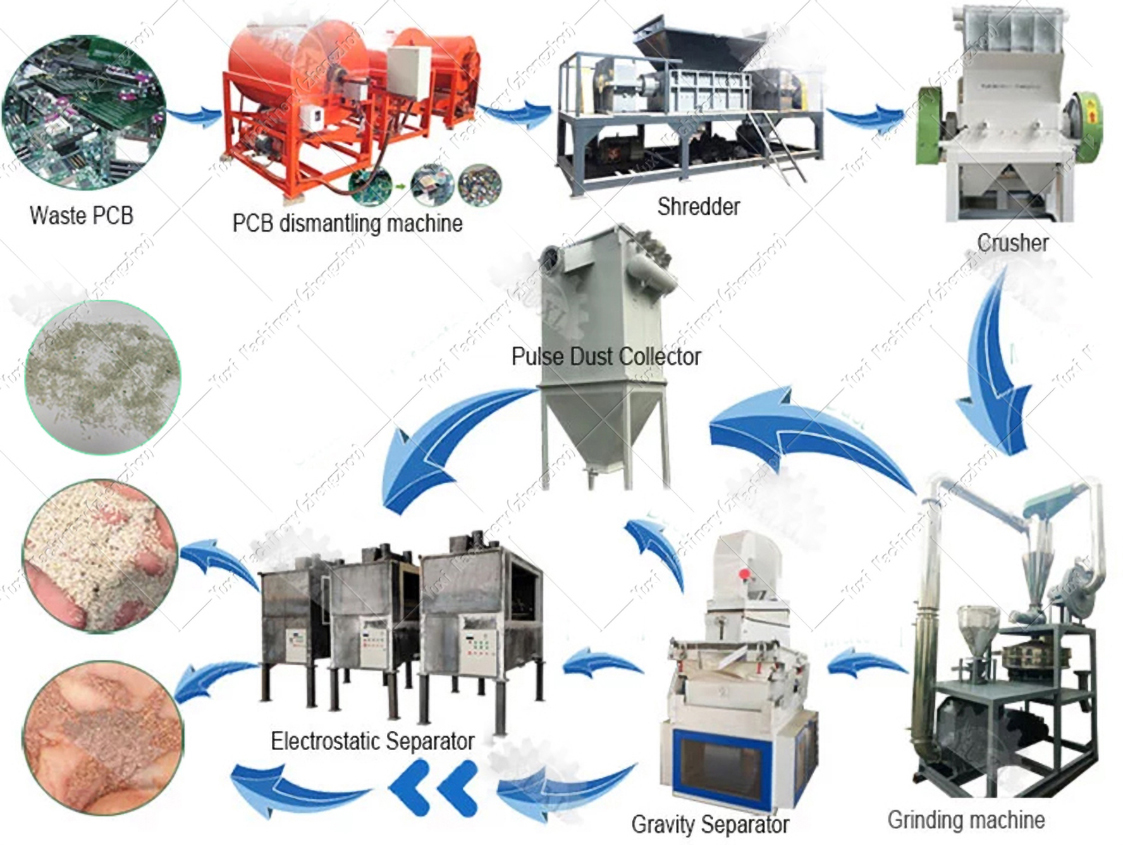

Main Equipment of PCB Recycling Machine

1.Double shaft shredder machine using high quality steel welding. And make sure the stability of the machine in the long heavy-duty working. Blade quality have 9CrSi, Cr12Mov, SKD-II, D2 etc. It can be customized according to the customer.

2.Hammer crusher crushes material into smaller size. It has high efficiency and stable performance. The discharge size can be adjusted, crusher blade can be removed.

3.Grinding System :New abrasive disk design, high capacity, good Wear Resistance, the service life is two times longer than the common abrasive disk.

4.Sorting System:The material is separated twice by air separator and electrostatic separator, Air

separation efficiency is up to 97%. Electrostatic separator can separate the metal and nonmetal material again by the second roller, to improve the purity of the metals.

5.Dust Collection System:Pulse dust collector and bag dust collector are combined. High efficiency of dust removal; dust particle with a diameter more than 0.3 micrometers can be

gathered, and the dust collection efficiency is up to 99%.

Working Principle

The production line consists of shredding system, milling system, sorting system and dust collection system. The whole process is controlled by PLC.

Through shredding, grinding, vibration screening,(the incompletely separated metal and nonmetal will reentry into the grinding machine to be grinded again) gravity separating, electrostatic separating and pulse dust collecting, the metal and nonmetal will reach about 99% of separation,eventually get metal and non-metallic collective, and the valuable components after dismantling machine can also be recycled refined.

Feature

1.The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2.Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3.The crushing part uses shredding, smashing and crushing processes, and circulating water cooling is used inside and outside the crushing chamber.

4.Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

5.The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.

Test and Inspection

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet customer requirement. We sincerely invite customers came to the scene for final test.

Please click on "WhatsApp" contact us at any time.